Nippon Steel

The leading company contributing to society through the Steel making business. Japan’s first

modern steel making company established in Kitakyushu in 1901. Now, becoming the best

steel maker with World-leading capabilities.

Product and application

Steel sheet for automobile, bar, and gear connecting rod

Tinplate for juice cans and food cans, wire rod and cold forged parts

Spiral pipes for steel slit dam

Rails for JR train and new bullet train

Electrical steel sheets for potential transformer

Stainless steel plates for beer tanks

What to learn

・Process up to completion of products

・History of Japan’s Industrial modernization

・Japanese quality control system

Where to visit

・Blast Furnace

Melted Pig iron with 1,500 degree celsius is produced from the iron ore

・Hot rolling mill plant

1 to 25 mm thickness plate is produced from 250 mm thick plate

|

The Exhibition hall, introduce the Steel making process |

Tobata No. 4 Blast Furnace, where more than 12,000ton iron is produced a day |

Hot Strip Mill where 1 to 2.5 mm thin plates is produced from 250mm thick plates |

General information

| Address | 1-1 Tobihata, Tobata, Kitakyushu-city, Fukuoka-prefecture |

| Access | 20 minutes by a vehicle from JR Kokura Station |

| Days of visit | Weekdays except Saturdays, Sundays and National Holidays |

| Fee | No visiting fee is required |

| Booking | Can be made by Japan KYUSHU Tourist |

TOYOTA Motor Kyushu

Established in 1991, 100% shareholder of Toyota Motor. Major manufactured car is Lexus,

and annual production volume is 430,000 cars.

Assembly line and Inspection line are visited at the factory tour.

|

|

|

General information

| Address | 1 Kamiaruki, Miyawaka-city, Fukuoka-prefecture |

| Access | 60 minutes by a vehicle from JR Kokura Station |

| Days of visit | Weekdays except Saturdays, Sundays and National Holidays |

| Fee | No visiting fee is required |

| Booking | Can be made by Japan KYUSHU Tourist |

Home Tailor-made tours Study tours Christian Pilgrimage tours Golf tour Kyushu tour packages

Study tour in the STEM Education field

and Mathematics) as well as Japanese Culture.

|

Learn Science, Environment, Nature, Industry, various history |

Field of science devoted to the study of the lands, features, inhabitants, phenomena of Earth |

Various unique architectures designed by renowned designers |

Your equiry can be sent by selecting the Enquiry Form link below.

You can also contact us by e-mail at info@japan-kyushu-tourist.com

Tel : +81-93-521-8897 , Fax : +81-93-521-8898

Address : AIM buiding 6th floor, 3-8-1 Asano, Kokura-kitaku, Kitakyushu-city, Fukuoka-prefecture

HOME About us Our Services Terms and Conditions

Recycling & Waste treatment technologies tour

Kitakyushu is offering various Recycling and Waste treatment technologies.

Kitakyushu City, once known as a “town of pollution,” now plays the role of the driving

force in creating a recycling-oriented society in Japan making use of the experience

and know-how it accumulated in the process of overcoming its pollution in order to

provide international cooperation. Our study tour provides the solutions of Recycling

and waste treatment issues

Model of the tour

・Lecture of Recycling and waste treatment

Lecturer : Masa Kondo, managing director of Japan KYUSHU Tourist

(have expertise and experience in the technical field)

Content of lecture

History to Environmental Future city

World leading Recycling and waste treatment business

Venue : Kitakyushu Innovation Gallery

Where to visit

Please select from the following

Eco Project information center that supports the Eco-town. It introduces initiatives and activities

implemented in Eco-town to encourage people to proactively used the facility for such activities

as environmental study sessions and interaction amongst visitors.

|

|

|

Plastic PET Bottle recycling / Nishi-Nippon PET Recycling

PET (polyethylene terephthalate) bottles are sorted by municipalities and recycled into pellets and

flakes, which can be used as raw materials for polyester fibers and egg cartons.

|

|

|

Melting Furnace / Sin-Moji Plant

The collected waste including metals is melted at over 1,700 degree Celsius in the Melting Furnace

and then the melted slag and metals are discharged. The slag is used as raw materials for pavement

and bricks and the metals are re-used for other steel products. The process and technology of the

Melting Furnace can be learned.

|

|

|

Waste paper recycling / Kyushu Seishi

Refined waste papers is recycled into toilet papers. Sludge generated during the toilet paper

production process is used to produce a foaming inhibitor used by steel works.

|

|

|

Hiagari Sewage water treatment plant

The sewage come through the sewer pipe is purified in the plant and flow into the sea. There is an

also new technology plant which the electricity is generated using the sludge from sewage. At the

Visitor Center established in 2015, sewage treatment process and technologies can be learned.

|

|

|

Your equiry can be sent by selecting the Enquiry Form link below.

You can also contact us by e-mail at info@japan-kyushu-tourist.com

Tel : +81-93-521-8897, Fax : +81-93-521-8898

Address : AIM buiding 6th floor, 3-8-1 Asano, Kokura-kitaku, Kitakyushu-city, Fukuoka-prefecture

HOME About us Our Services Terms and Conditions

Low Carbon Society in Kitakyushu-city

Kitakyushu-city is promoting the low carbon society in Asia while taking leadership as the

Environmental Future City. The new generation technologies and the activities cooperated

with Citizen to achieve low carbon society can be learned.

Eco Project information center that supports the Eco-town. It introduces initiatives and activities

implemented in Eco-town to encourage people to proactively used the facility for such activities

as environmental study sessions and interaction amongst visitors.

|

|

|

Zero Emission Transportation System

The Electric bus driven by the electricity generated by a solar power generation, therefor no global

warming gases emitted from the bus. Operation of the system is commenced in 2015.

The solar power generation plant, the power charging equipment and Electric bus can be observed.

|

Solar Power Generation |

Electric bus |

on the bus |

Japan’s first wind power generation plant constructed at the coast line facing windy strong

Hibikinada sea. 10 wind power generators line up and total generation capacity is 15,000kw.

|

|

|

The company have been supplying low-cost and reliable electricity for over 60 years.

And research and development of the environmental measurement have been conducted.

New solar power generation and wind power generation systems can be learned.

|

|

|

Kyushu Electric Power / Shin-Kokura Plant

Kyushu’s first thermal power plant used LNG and power generation capacity is 1,800,000kw.

Generation of electricity process can be learned by visiting the turbine room, control room and

boiler plant.

|

|

|

Should you need further information please feel free to contact us.

Your equiry can be sent by selecting the Enquiry Form link below.

You can also contact us by e-mail at info@japan-kyushu-tourist.com

And we would love to chat about your travel plans on the phone as well,

please ring our office a call in English Tel : +81-93-521-8897

HOME About us Our Services Terms and Conditions

Industrial Heritages in Kitakyushu

Kitakyushu-city is the industrial innovation city where a lot of Japan’s Industries were born

and Japan’s industrial modernization has been achieved. The city presents various Industrial

Heritages including UNESCO World Herigate of Japan’s Meiji Industrial Revolution.

First Head Office of the Steel Works UNESCO World Heritage

Built in 1899, ahead of production facilities. It is an architectural fusion of Japanese and

European design, a two story red brick building with bilateral symmetry and a central dome

set in a Japanese tile roof.

|

World leading rails producing in the Steel Works |

First Head Office building registered on the World Heritage |

Observation deck of the World Heritage |

Onga River Pump Station, UNESCO World Heritage

Built in 1910 on the east bank of the Onga River. It served, and still serves, to deliver industrial

water to Yawata via an 11.4 km pipeline. This supply is integral to the steel production process

and was necessary to cope with the 1st phase expansion of the Imperial Steel Works.

|

Onga River |

Onga River Pump Station |

Water piping to the Steel Works |

The first-class civil construction heritage that triggered the registration of World Cultural Heritage of

Meiji Japan’s Industrial Revolution.Th e Kawachi Reservoir was constructed for the industrial water

supply to Yawata Steel Works.

|

|

|

The Blast Furnace used to make the pig iron and was where Japan’s steel industry began in 1901.

It contributed greatly to the development of the Japanese steel industry and was used until 1972,

and has been preserved just as it was.

|

Indication of the year of Steel Works operation commencement |

Proper of Blast furnace, Hot Stoves and Stack |

Cast house floor, the pig iron is being discharged |

Dedicated railway for Yawata Steel Works

Connected between Yawata and Tobata. Construction work took three years, and completed in

1930. The most difficult and hard work was making Miyatayama tunnel with a total length of 1180m

due to suffering from floods. The gates of the Miyatayama tunnel are decorated with stately designs.

|

The rail way crossing the road |

Miyatayama tunnel Yahata side |

Miyatayama tunnel Tobata side |

Your equiry can be sent by selecting the Enquiry Form link below.

You can also contact us by e-mail at info@japan-kyushu-tourist.com

And we would love to chat about your travel plans on the phone as well,

please ring our office a call in English Tel : +81-93-521-8897

HOME About us Our Services Terms and Conditions

Solid Waste management & Recycling technologies in Kitakyushu

Historically, waste management systems focused on collection and disposal waste to protect

the health of city inhabitants and to improve the aesthetic appearance of territories. 19th century,

as cities grew and industrialized, more waste was produced and its composition changed dramatically.

Environmental protection and conservation started to receive increasing attention, and by the 20th

century waste was increasingly viewed also as a resource to recover materials and energy.

In the more economically developed countries, waste management gradually evolved from a focus

on disposal to a focus on prevention, recycling, and recovery.

Now, Japan is a global leader in the development and application of environmental policy in the

waste sector and Kitakyushu-city is the advanced city of solid waste management in Japan.

Solid waste management in Kitakyushu-city

Comprehensive solid waste management system can be learned from waste collecting procedure

at household to the final stage of waste treatment such as incineration, landfill and recycling.

Visitor Center

Eco Project information center that supports the Eco-town. It introduces initiatives and activities

implemented in Eco-town to encourage people to proactively used the facility for such activities

as environmental study sessions and interaction amongst visitors.

|

|

|

The museum has Environmental learning function, Environmental information function and

Environmental activity function. The Environmental improvement history of Kitakyushu, Global

warming and other various environmental issues can be learned.

Waste Collecting and separating facilities

・Hiagari can and bottle recycling Center

・Honjo can and bottle recycling Center

・Hiagari bulky garbage recycling Center

Recycling facilities

Plastic PET Bottle recycling / Nishi-Nippon PET Recycling

PET (polyethylene terephthalate) bottles are sorted by municipalities and recycled into pellets

and flakes, which can be used as raw materials for polyester fibers and egg cartons.

|

|

|

Waste paper recycling / Kyushu Seishi

Refined waste papers is recycled into toilet papers. Sludge generated during the toilet paper production

process is used to produce a foaming inhibitor used by steel works.

|

|

|

Other facilities

・Plastic material recycling

・Office equipment recycling

・Automobile recycling

・Home Appliance recycling

・Fluorescent tube recycling

・Medical instrument recycling

・Mixed construction waste recycling

・Comprehensive nonferrous metal recycling

・PCB-polluted soil purification project

・Cooking oil recycling

・Can recycling

Final treatment facilities

Melting Furnace / Sin-Moji Plant

The collected waste including metals is melted at over 1,700 degree Celsius in the Melting Furnace

and then the melted slag and metals are discharged. The slag is used as raw materials for pavement

and bricks and the metals are re-used for other steel products. The process and technology of the

Melting Furnace can be learned.

|

|

|

Other facilities

・Kogasaki Incineration Furnace

・Hibikinada Landfill area

Other facilities related to Recycling and Waste management

World’s first hydrogen station for vehicle to utilize the wastewater treated in the Fukuoka Chubu

Sewage Treatment Center. The process has been developed as a result of the verification testing

of technology for hydrogen creation sourced from wastewater biogas.

|

|

|

The biomass recycling facility that started operations in November 2006.It takes kitchen waste

from the town’s households and restaurants, along with septic tank sludge and raw sewage,

and uses a methane fermentation process to turn it into a biomass that can be used for power

generation. After the fermentation, the digestive fluids are used as liquid fertilizer. Furthermore,

Oki Town was the second in the country to make a zero-waste declaration, which it officially

announced in March 2008 with its Oki Town Mottainai Declaration.

|

|

|

Hiagari Sewage water treatment plant

The sewage come through the sewer pipe is purified in the plant and flow into the sea. There is an

also new technology plant which the electricity is generated using the sludge from sewage. At the

Visitor Center established in 2015, sewage treatment process and technologies can be learned.

|

|

|

The Plant making fresh water from sea water and sewage water established in 2011.

The desalination process and technology can be leared.

|

|

|

Nippon Steel / Yawata Works

Japan’s first modern steel making company established in Kitakyushu in 1901. Now, becoming

the best steel maker with World-leading capabiities. Process of steel making can be learned to

visit Blast Furnace and Hot rolling mill plants.

|

|

|

Japan’s largest Biotope, the Pradise of creatures made over the year in the waste disposal site.

237 kind of birds including circus spinouts listed on the Japan’s endangered species and 284 kind

of vegetation have been confirmed in the Biotope of 41 hectares.

|

|

|

Your equiry can be sent by selecting the Enquiry Form link below.

You can also contact us by e-mail at info@japan-kyushu-tourist.com

Tel : +81-93-521-8897 , Fax : +81-93-521-8898

Address : AIM buiding 6th floor, 3-8-1 Asano, Kokura-kitaku, Kitakyushu-city, Fukuoka-prefecture

Hiagari Sewage water treatment plant

The sewage come through the sewer pipe is purified in the plant and flow into the sea. There

is an also new technology plant which the electricity is generated using the sludge from sewage.

At the Visitor Center established in 2015, sewage treatment process and technologies can be

learned.

|

|

|

General information

| Address | 96-3 Nishiminato-machi, Kokura-kitaku, Kitakyushu-city, Fukuoka-prefecture |

| Access | 20 minutes by a vehicle from JR Kokura Station |

| Days of visit | Weekdays except Saturdays, Sundays and National Holidays |

| Fee | No visiting fee is required |

| Arrangment | Japan KYUSHU Tourist organize to visit |

Your equiry can be sent by selecting the Enquiry Form link below.

You can also contact us by e-mail at info@japan-kyushu-tourist.com

Tel : +81-93-521-8897, Fax : +81-93-521-8898

Address : AIM buiding 6th floor, 3-8-1 Asano, Kokura-kitaku, Kitakyushu-city, Fukuoka-prefecture

HOME About us Our Services Terms and Conditions

Kitakyushu study tour / where to visit

Where to visit

Manufacturing companies

Nippon Steel and Sumitomo Metal / Yawata Works

Japan’s first modern steel making company established in Kitakyushu in 1901. Now, becoming

the best steel maker with World-leading capabiities. Process of steel making can be learned to

visit Blast Furnace and Hot rolling mill plants..

|

|

|

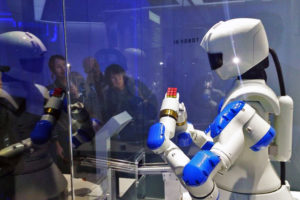

World-leading motor and industrial robots manufacturing company established

in Kitakyushu in 1915. The robots are heavy duty industrial robots used in welding, packing,

assembly, painting and other activities.

Robot manufacturing factory and Yaskawa Innovation Center can be visited.

|

|

|

The world’s largest toilet manufacturer established in Kitakyushu in 1917.

The company is well-known in Washlet which is an innovative toilet seat that features an

integrated bidet. The sanitary ware manufacturing factory and TOTO Museum can be visited

|

|

|

The roots of NISSAN is Tobata Casting funded in Kitakyushu in 1911.

The factory was commenced operation in 1975. Now TEANA, X-TRAIL ROGUE, SERENA

and MURANO are being manufactured. The process from assembly of the parts to final

products can be seen.

|

|

|

Established in 1991, 100% shareholder of Toyota Motor. Major manufactured car is Lexus,

and annual production volume is 430,000 cars. Assembly line and Inspection line are visited

at the factory tour.

|

|

|

Environmental companies and facilities

Eco Project information center that supports the Eco-town. It introduces initiatives and activities

implemented in Eco-town to encourage people to proactively used the facility for such activities

as environmental study sessions and interaction amongst visitors.

|

|

|

Zero Emission Transportation System

The Electric bus driven by the electricity generated by a solar power generation, therefor no global

warming gases emitted from the bus. Operation of the system is commenced in 2015.

The solar power generation plant, the power charging equipment and Electric bus can be observed.

|

Solar Power Generation |

Electric bus |

on the bus |

Japan’s largest Biotope, the Pradise of creatures made over the year in the waste disposal site.

237 kind of birds including circus spinouts listed on the Japan’s endangered species and 284 kind

of vegetation have been confirmed in the Biotope of 41 hectares.

|

|

|

Power generation plants

Kyushu Electric Power / Shin-Kokura Plant

Kyushu’s first thermal power plant used LNG and power generation capacity is 1,800,000kw.

Generation of electricity process can be learned by visiting the turbine room, control room and

boiler plant.

|

|

|

The company have been supplying low-cost and reliable electricity for over 60 years.

And research and development of the environmental measurement have been conducted.

New solar power generation and wind power generation systems can be learned.

|

|

|

Japan’s first wind power generation plant constructed at the coast line facing windy strong

Hibikinada sea. 10 wind power generators line up and total generation capacity is 15,000kw.

|

|

|

Waste treatment and recycling companies and facilities

Plastic PET Bottle recycling / Nishi-Nippon PET Recycling

PET (polyethylene terephthalate) bottles are sorted by municipalities and recycled into

pellets and flakes, which can be used as raw materials for polyester fibers and egg cartons

|

|

|

Melting Furnace / Sin-Moji Plant

The collected waste including metals is melted at over 1,700 degree Celsius in the Melting

Furnace and then the melted slag and metals are discharged.

The slag is used as raw materials for pavement and bricks and the metals are re-used for

other steel products. The process and technology of the Melting Furnace can be learned.

|

|

|

Waste paper recycling / Kyushu Seishi

Refined waste papers is recycled into toilet papers.

Sludge generated during the toilet paper production process is used to produce a

foaming inhibitor used by steel works.

|

|

|

Water treatment plants and facilities

Hiagari Sewage water treatment plant

The sewage come through the sewer pipe is purified in the plant and flow into the sea.

There is an also new technology plant which the electricity is generated using the sludge from sewage.

At the Visitor Center established in 2015, sewage treatment process and technologies can be learned.

|

|

|

The Plant making fresh water from sea water and sewage water established in 2011.

The desalination process and technology can be leared.

|

|

|

Food waste recycle

Merry Corporation

The food waste recycling company that the compost is being produced from food waste discharged

from food factories, hospitals, restaurants and municipal facilities.

|

|

Should you need further information please feel free to contact us.

Your equiry can be sent by selecting the Enquiry Form link below.

You can also contact us by e-mail at info@japan-kyushu-tourist.com

Tel : +81-93-521-8897, Fax : +81-93-521-8898

Address : AIM buiding 6th floor, 3-8-1 Asano, Kokura-kitaku, Kitakyushu-city, Fukuoka-prefecture

Environmental improvement history of Kiyakyushu

The city once experienced the worst air pollution in Japan

Saw Dokai Bay turned into a “sea of death.” But it regained blue skies after

overcoming its pollution problem by the efforts of city, companies as well

as the women’s association.

Kitakyushu City, once known as a “town of pollution,” now plays the role of the driving

force in creating a recycling-oriented society in Japan making use of the experience

and know-how it accumulated in the process of overcoming its pollution in order to

provide international cooperation.

The city grew as an industrial city after the establishment of Yawata Steel Works in 1901.

It led Japan during the period of modernization and high economic growth with a focus

placed on heavy industry.

Back then, plumes of smoke coming out of the steelworks were referred to as

“seven-colored smoke” which was sung as part of the lyrics of the song of former

Yahata City as it was regarded as a symbol of prosperity. However, the prosperity

of industries brought about severe pollution and quite naturally the “seven-colored

smoke” polluted the air and caused dust deposition.

In the 1960s, air pollution in the Kitakyushu area was the worst in Japan and Dokai

Bay was turned into a “sea of death” due to effluent from factories.

It was citizens who first noticed this problem of pollution. The city started to hear the

voices of its residents saying such things as, “my house is becoming sandy” and

“the laundry gets dirty” from around 1950. The Women’s Association in Tobata area

stood up, investigated the problem themselves and asked the council, administration

and companies to take measures against pollution. ‘I Want Blue Sky’, a documentary

film produced by the Tobata Women’s Association in 1965 was what symbolized the

citizens’ campaign calling for measures against pollution.

Pushed by the voices of its citizens, the Kitakyushu administration started to take action

to grasp the actual situation by measuring the level of air pollution. It then gave

instructions and conducted on-site inspections at these companies urging them to take

measures to improve the situation. Finally, the city concluded a pact on pollution

prevention with each plant and established the Council on Air Pollution Prevention

made up of the city, Fukuoka Prefecture, then Regional Bureaus of International

Trade and Industry and about 30 companies in the city. These companies

responded by putting pollution control facilities in place as well as improving the process

of production.

In the meantime, the Air Pollution Control Act and Noise Regulation Act came into

force in 1968 and the following year, in 1969, a smog alert was issued for the first

time in Japan.

Fourteen pollution control related bills passed the so-called ‘Pollution Diet’ in 1970.

Thus, public concern towards pollution problems grew high throughout Japan while in

Kitakyushu, the city and companies worked hand in hand to tackle the pollution

problem which resulted in rapid improvement in the environment.

As a result, by around 1980, the blue sky came back to the town once covered with ‘

seven-colored smoke.’ Furthermore, over 100 species of fish live in Dokai Bay which

was once nicknamed the ‘sea of death’ where not even bacteria could live.

In 1985, the Organization for Economic Co-operation and Development (OECD)

introduced Kitakyushu in its White Paper on the environment as a city that transformed

itself from a ‘Gray Town’ into a ‘Green Town.’ Also the city was selected as one of the

‘Starry Towns’ with a favorable atmospheric environment in the ‘Starry Town Contest’

held by the Environment Agency in 1987.

These initiatives by Kitakyushu City are highly recognized by the global society. In 1990,

the city received the ‘Global 500 Award’, which is given by the UN Environment

Program (UNEP) to individuals and organizations that combat environmental issues,

and was the first local government to win the Award in Japan. At the Earth Summit

held in Rio de Janeiro, Brazil in 1992, Kitakyushu City was honored with the ‘Local

Government Honors Award. The city is the only local government to win the Award

in Japan.

In addition, the initiative towards a better environment was enhanced and it started the

sorted collection of cans and bottles in 1993. In 1998, a system in which residents are

obliged to use designated plastic bags for municipal waste started. In 2001,

‘Kitakyushu Expo-Festival 2001’ with the environment as a theme was held at

Higashida area, an idle land owned by Nippon Steel Corporation, where infrastructure

improvement work was going on based on the concept of ‘Kitakyushu Renaissance.

Then, the concept of a ‘Green Village’ in Yahata Higashida began in 2003.

Thus, efforts towards a better environment advanced further.

As mentioned above, Kitakyushu was recognized as the ‘Environmental Model City’

together with 12 other local governments in 2008. The ‘Kitakyushu Asian Center for

Low Carbon Society’ was opened in 2010, and in 2011 the city was selected as a

‘Environmental Future City’ and also as the first ‘Model City for Green Growth’ in

Asia by the Organization for Economic Co-operation and Development (OECD).

A new challenge as the driving force towards realizing a global low carbon society

has started in Kitakyushu City where Japanese industry started.

Should you need further information please feel free to contact us.

Your equiry can be sent by selecting the Enquiry Form link below.

You can also contact us by e-mail at info@japan-kyushu-tourist.com

Tel : +81-93-521-8897 , Fax : +81-93-521-8898

Address : AIM buiding 6th floor, 3-8-1 Asano, Kokura-kitaku, Kitakyushu-city, Fukuoka-prefecture